1. (VOCs)

volatile organic compound

administer

Main process

Step 1 Preprocessing

· Dust removal: water washing, filtration, etc.

· acid removal / alkali: neutralization absorption

· dehumidification: heating, condensation-heating

· cooling: heat exchanger

Step2 the main processing process

· zeolite molecular sieve adsorption

· activated carbon adsorption

· RTO / RCO / CO / TO

· condensation method

· biological method

· process combination

Step3 the post-processing process

· acid removal: neutralization absorption

· NOx: catalytic reduction

· Erga ying: adsorption method

2. VOCs recovery and emission reduction technology based on special material adsorption

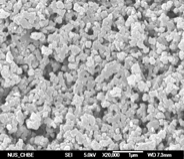

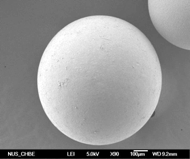

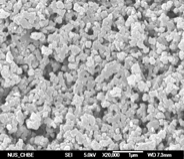

Special adsorption material is high molecular polymer

|

adsorbent

|

Activated carbon fiber

|

acticarbon

|

Special adsorption materials

|

|

adsorbed object

|

Not suitable for ketones, esters, halogenated hydrocarbons, etc

|

Not suitable for ketones, esters, halogenated hydrocarbons, etc

|

No restrictions

|

|

Removal efficiency

|

Gradually attenuation

|

Gradually attenuation

|

High,stable

|

|

Replacement cycle

|

2~3 Years

|

6 months to1year

|

non-renewal

|

|

Steam dosage (per ton of solvent)

|

7~10t

|

7~10t

|

2~3t

|

This technology has high mechanical strength and stable adsorption performance, so it is successfully applied to the treatment of dichloromethane, dichloroethane, chloroform, toluene, ethyl ethyl methyl isobutylmethyl one, n-hexane and 120 # solvent oil, which is especially suitable for the recycling of chlorine-containing organic matter.

For more information or cooperation, please email: sales@kgmatzen.com